Showing 1–12 of 19 results

GL-120KN CNC Steel bar shear line

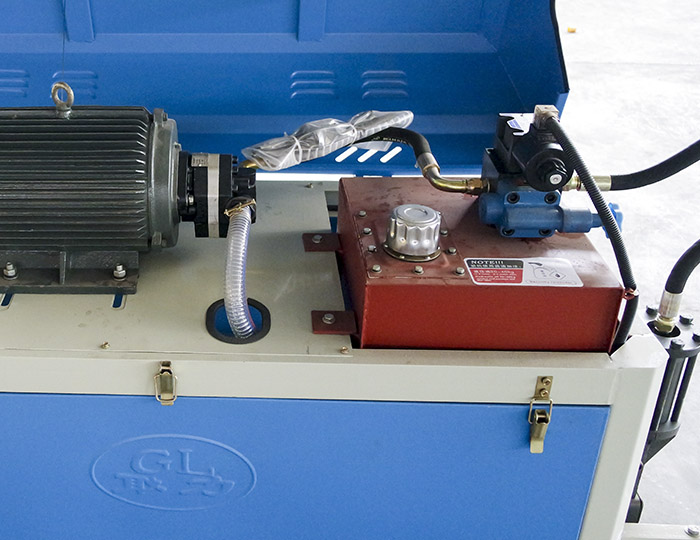

GL-450L CNC steel bar sawing, upsetting, threading and polishing production line

- Maximum machining diameter (round steel): ≤ 50 mm

- Rebar conveyor speed: 58-62m/min

- Thread length: ≤90 mm

- Total power/total power consumption: 40 Kw

- Single-end threading time: 25S~40S

Applied range:The GL-450L CNC steel bar sawing, upsetting, threading and grinding production line is a highly automated steel bar processing equipment that integrates automatic storage, feeding, sizing, sawing, piercing, threading, grinding, locating, and grading storage. The maximum diameter of sawn steel bars is 50mm.

GL-G2L32 CNC Steel bar bending center

GL-L32T5 CNC Steel bar bending center

GL110Ⅱ-248 Mobile Air Compressor

GL1500-2500 Steel reinforcement cage seam welder

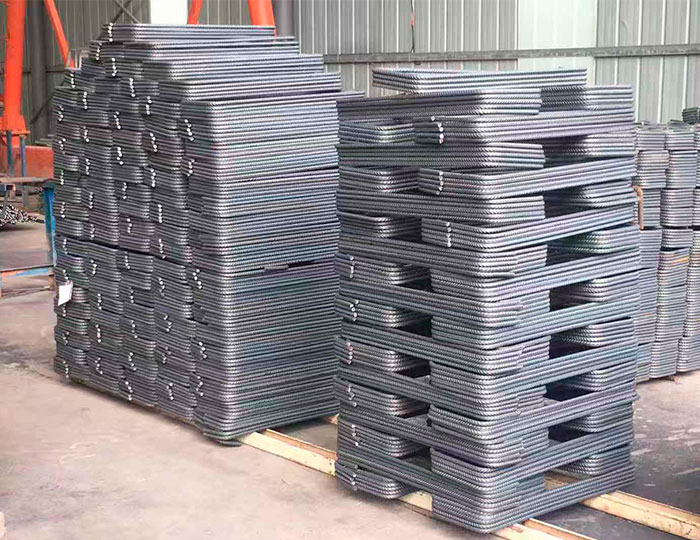

GL4-12 Steel bar straightening and cutting machine

- Straightening diameter range:Ф4-12mm

- Traction speed:45m/min,48m/min

- Fixed length:300-9000mm(can be lengthed)

- Cutting length tolerance:±10mm

Applied range:Mainly used for straightening and cutting to length, suitable for cold-rolled grade III steel bars, cold-rolled round steel bars for construction, and adjustable straight hot-rolled round steel bars.

GL4-16A CNC Hydraulic Bar Straightening and Cutting Machine

- Straightening diameter range:Ф4-16mm

- Traction speed:45m/min,48m/min

- Fixed length:300-9000mm(can be lengthened)

- Cutting length tolerance :±10mm

Applied range:Mainly used for straightening and cutting to length, suitable for cold-rolled grade III steel bars, cold-rolled round steel bars for construction, and adjustable straight hot-rolled round steel bars.